Industries Served

OEM Manufacturing

Original Equipment Manufacturers (OEMs) build equipment, systems, tools, and devices sold to end-users in countless markets. From heavy manufacturing equipment to handheld medical devices, OEMs choose components for their systems that they trust to share their brand name. Buyers in the OEM industry rely upon Whitman Controls to deliver high-quality, reliable, and resilient instruments to include in their designs.

Semiconductor Manufacturing

Semiconductor manufacturers operate on scales far beyond what most of us can fathom, producing microelectronic devices that connect continents (and even planets) using technologies that operate in the realm of nanometers. As the Semiconductor industry continues to break boundaries, precision instrumentation and process controls must reach new heights in reliability, accuracy, and integrity to keep pace – precisely the mission that Whitman Controls’ sensors and instruments serve best.

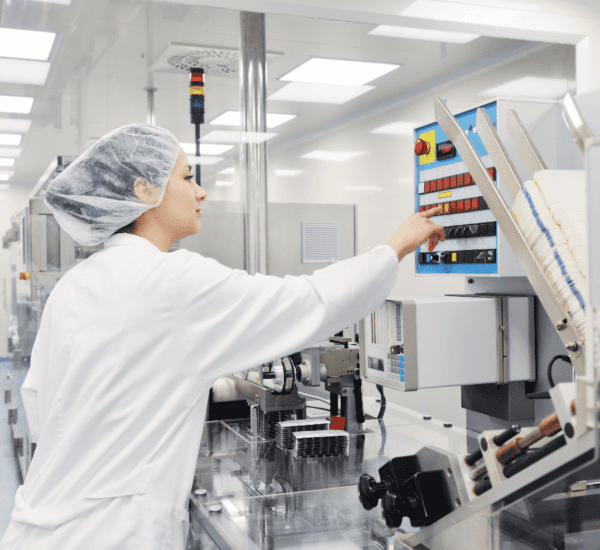

Medical & Pharmaceutical

When human health and safety are the subject, an unwavering commitment to process integrity is the only acceptable starting point. The Medical Device and Pharmaceutical Manufacturing industries collectively hold public trust in their hands, and earn that trust through safe, consistent, dependable production of goods and treatments. Process control technologies play an increasingly critical role in these industries, a role that Whitman Controls embodies through our wide range of engineered, hygienic, ultra-reliable instrumentation.

Oil & Gas

The world consumes an estimated 100 million barrels of petroleum each day, a figure that is perpetually on the rise. The Oil & Gas Industry is to thank for nearly all of the energy and consumer products we use in our daily lives – from fuel to asphalt, plastics to even aspirin. Optimizing petroleum processes therefore is a crucial task towards getting the most out of this precious resource, a job that calls for world-class process controls and instrumentation.

Alternative Energy

Most energy consumed by humans across the world comes from oil, coal, and natural gas – all of which are finite resources. The need for alternative fuel sources is unprecedented, both to fulfill ever-increasing demand as well as to reduce fuel-burning environmental burdens at a global scale. Wind, geothermal, solar, hydroelectric, biodiesel, hydrogen, and biomass energy sources are our current most viable options, and advanced process control instrumentation plays a significant role in supporting these technologies as they scale up.

Food & Beverage

They say that great food comes from great ingredients, but we say that safe food comes from even safer food process manufacturing controls. Hygienic processes found in the US Food and Beverage Industry must be both ultra-reliable and incredibly dynamic, as feeding a nation of 332 million people under control of the world’s foremost food safety regulations is no simple matter. Whitman Controls earns our seat at the table by offering instrumentation specifically engineered for these demanding applications.

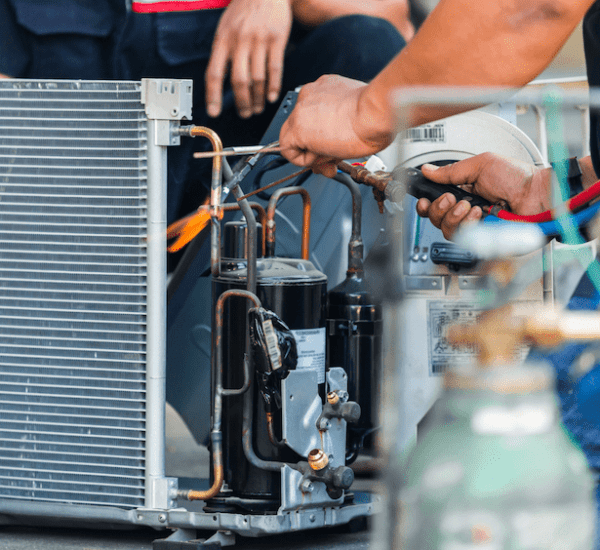

HVAC

While the necessities of life might not officially include heating and air conditioning, most of us would be significantly impacted if we had to go through life completely exposed to our local climate without relief. The HVAC Industry provides us with this relief by heating, ventilating, and air conditioning indoor spaces to our comfort, thanks to advanced mechanical systems and sophisticated controls that keep outside weather outside, and cozy atmospheres within.

Water & Wastewater

There is likely no engineering domain more quintessential to human existence than managing water. Across civilized history, humans have diverted water out of the ecosystem, used it for some functional purpose, and returned what was left over, all while figuring out ways to make that water safe, clean, and dependable. Known today as the Water and Wastewater Industry, the goals remain the same – only now, water is managed at global scales, serving the needs of billions.

Transportation & Vehicles

If the modern world runs on commerce, then commerce itself runs on transactions involving goods and services, most of which require resources from one location to be transported to another in order to complete the exchange. The Transportation industry makes all of this possible, whether by truck, bus, rail, plane, sea ship, or even spaceship – each relying on sophisticated control systems for their reliable, safe, on-time operation.

Chemical

As far back as the so-called primordial soup, the history of the world is that of chemical reactions and all the interesting things they’ve led to. The Industrial Chemical manufacturing sector has picked up where mother nature left off, affording us the wonders of modern materials found in virtually every aspect of our lives, largely thanks to advanced, safe chemical process controls.